The automatic smelt spout cleaning robot ensures a more consistent flow in the smelt spout without interruptions, reducing the risk of functional problems and damage to the dissolving tank. This improves the chemical recycling process, potentially leading to fewer chemical losses and reduced NOx emissions.

A smooth flow in the smelt spout minimizes temperature fluctuations, allowing for longer replacement intervals and increased cost efficiency. In automatic rodding, the rodding robot’s tool leaves a frozen melt on the tube bends opening, contributing to longer replacement intervals for boiler tube bends and lower maintenance costs.

Teknik Support’s smelt spout robot’s rodding tool avoids contact with the inner upper and lower parts of the smelt spout, where damage is most likely to occur. This approach leads to longer replacement intervals for the smelt spout, reducing maintenance costs and the risk of a factory shutdown.

If equipment breaks down and needs to be repaired there is a big risk of personal injuries in the smelt spout area. Teknik Support have developed a strong construction that can withstand difficult operating conditions. This means that we at Teknik Support have a smelt spout robot that is extremely reliable. We can guarantee 98 % availability on our equipment.

Additional equipment is employed to thoroughly inspect Teknik Support’s deliveries during the manufacturing process, ensuring their integrity before dispatch. Post-delivery modifications can be seamlessly executed at our service center. For recurring services, such as program changes, a meticulous testing process is implemented for the new software before its transmission to the customer through a GSM modem. This robust practice ensures the smooth functionality of the updated software, contributing to lower maintenance costs by eliminating the need for extensive travels.

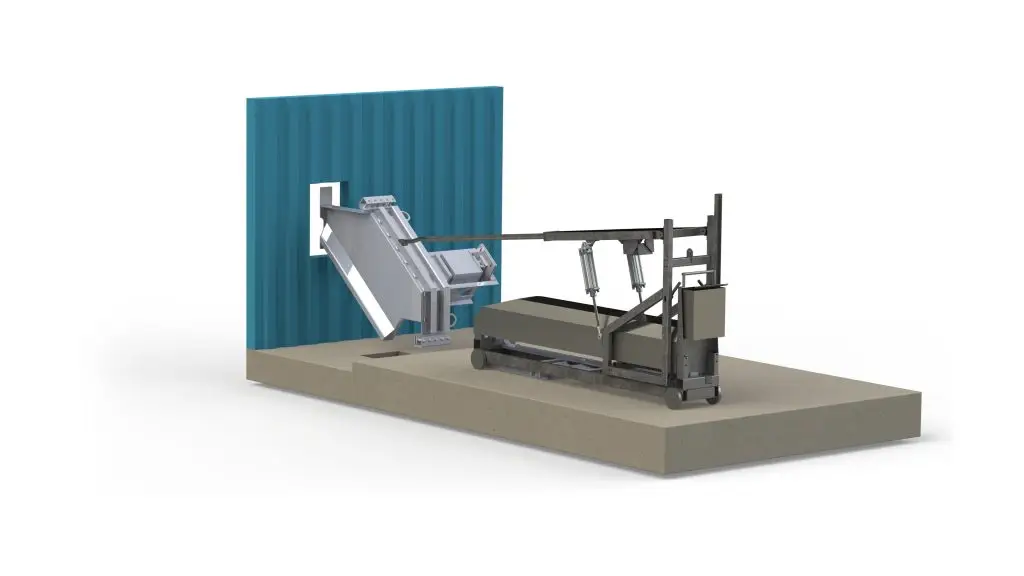

In the event that smelt spout cleaning robots require service at the manufacturer’s service center, our specialized shipping rig facilitates the process. This rig enables the placement of smelt spout robots on pallets of two, streamlining the shipping procedure and enhancing efficiency.